Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

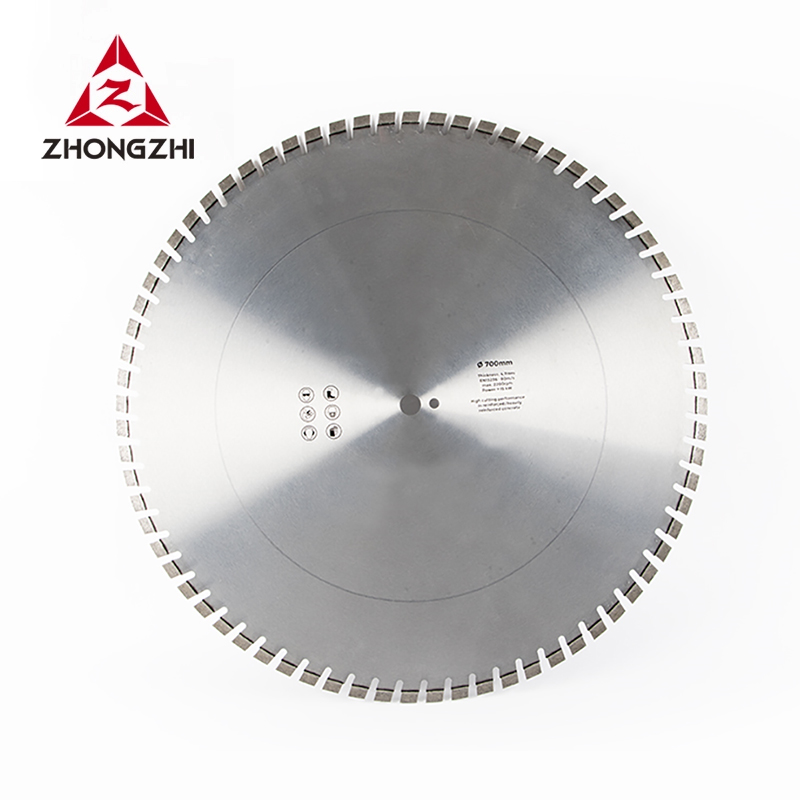

Diamond saw blades are essential tools for cutting tough materials like concrete, granite, and asphalt. Choosing the right diamond saw blade can make or break your project. In this article, we will explore the differences between laser-welded and hot pressed diamond blades. Understanding these differences will help you select the best blade for your needs, ensuring durability, performance, and cost-effectiveness.

Laser-welded blades are produced using a high-energy laser beam that melts a small portion of the diamond segment and the steel core. The laser fusion forms a strong metallurgical bond, ensuring that the segments stay attached to the core even under intense heat and pressure. This method allows for precise alignment, creating a blade with high cutting efficiency and durability.

Advantages:

Precision: The laser fusion process ensures a perfect bond with minimal heat-affected zones, preserving the segment integrity and making the blade highly durable.

High Strength: The process uses laser energy to create a robust bond, making laser-welded blades highly resistant to wear, making them ideal for high-intensity tasks.

Disadvantages:

Cost: The advanced technology involved in laser welding makes these blades more expensive to produce, resulting in a higher initial cost.

Hot-pressed diamond blades are made through a sintering process. In this method, diamond segments are pressed onto the steel core under high temperature and pressure. The heat helps the diamond matrix bond strongly to the steel, creating a dense, wear-resistant cutting surface.

Advantages:

Cost-Effective: The manufacturing process is more affordable, resulting in a less expensive blade.

Stability: The pressure and heat involved create a dense structure, ensuring a consistent cutting surface.

Disadvantages:

Weaker Bond: While the bond is strong, it isn’t as durable as the laser-welded bond. The segments can come loose more easily compared to laser-welded blades.

Longer Cutting Time: Hot-pressed blades are generally slower and less efficient when it comes to high-speed cutting.

The primary distinction between laser-welded and hot-pressed diamond blades lies in the bonding process. Laser-welded blades use a laser beam to precisely attach diamond segments to the core, while hot-pressed blades rely on heat and pressure to fuse the diamond segments. The laser-welded method results in a stronger bond and longer blade life, while hot-pressed blades, though more affordable, may wear out quicker under heavy use.

| Feature | Laser-Welded Blades | Hot-Pressed Blades |

|---|---|---|

| Bonding Process | High-energy laser fusion of segments and core | Sintering process with heat and pressure |

| Bond Strength | Stronger, more durable bond | Weaker bond, segments may loosen over time |

| Precision | High precision with minimal heat-affected zones | Moderate precision |

| Manufacturing Cost | Higher due to advanced technology | More affordable |

| Lifespan | Longer, especially for heavy-duty cutting | Shorter, may need more replacements |

Laser-welded diamond blades are known for their high cutting speed. Thanks to the precise attachment of the segments, these blades can efficiently transfer cutting forces, making them ideal for large-scale construction projects. They perform well even when cutting through tough materials such as thick concrete or stone, where speed and efficiency are crucial.

On the other hand, hot-pressed blades offer a smoother cut, but they are generally slower and not as suited for high-speed, heavy-duty tasks. These blades provide precision, which makes them more suitable for tasks requiring accurate cutting, such as decorative stonework.

Comparing Speed: Laser-welded blades tend to outshine hot-pressed blades in large-scale projects where speed is a primary factor. For instance, in road construction projects, laser-welded blades can quickly cut through thick concrete or asphalt without compromising the quality of the cut.

Laser-welded blades are more durable because the precise bonding ensures that the segments remain intact even during heavy-duty cutting tasks. However, the segments themselves can wear down quickly when cutting through extremely hard materials, requiring replacement after extended use.

Hot-pressed blades, while offering consistent cuts, tend to have a shorter lifespan because the segments are not as firmly bonded to the core. These blades are better suited for softer materials but need to be replaced or re-sharpened more frequently.

Durability Comparison: For example, in a high-volume construction environment where a large amount of tough material is being cut, laser-welded blades will last longer and handle the stress of heavy cutting with less wear compared to hot-pressed blades.

Laser-welded blades excel in high-demand applications such as road construction, demolition, and cutting thick concrete slabs. They are ideal when you need fast, efficient cuts over long periods.

Hot-pressed blades, in contrast, are best for detailed work like cutting countertops or intricate stone pieces. These blades offer smoother, more controlled cuts, making them perfect for decorative and precision-based tasks.

Laser-welded diamond blades generally have a higher initial cost because of the advanced technology involved in the laser-welding process. The precise manufacturing process leads to a more expensive blade. However, the longer lifespan and cutting efficiency often justify this higher cost.

Hot-pressed blades are typically more affordable to produce, making them a more budget-friendly option for projects where cost is a key concern. The trade-off is the slightly shorter lifespan and slower cutting speeds.

In terms of long-term value, laser-welded blades deliver greater performance and longevity, which can save costs over time by reducing the need for frequent blade replacements. For heavy-duty work, their higher upfront cost can be worthwhile.

Hot-pressed blades offer significant cost savings in the short run but may need to be replaced or sharpened more often, increasing long-term maintenance costs.

Long-Term Considerations: For professionals working on large projects, laser-welded blades provide excellent return on investment due to their longevity and performance. In contrast, for less demanding tasks, hot-pressed blades may suffice, providing good value without the high cost.

Laser-welded diamond blades are highly versatile. They can be used for both wet and dry cutting, which provides flexibility for a wide range of applications. Whether you're working with concrete, granite, or other hard materials, these blades are up to the task. This versatility makes them a popular choice for professionals working in diverse environments and with various materials.

While hot-pressed blades are mainly designed for dry cutting conditions, they can handle a variety of materials with precision. However, they are not ideal for wet cutting, as the heat generated could weaken the bond between the segments and the core. This limits their overall versatility compared to laser-welded blades.

Versatility Breakdown:

Laser-Welded: Ideal for both wet and dry cutting, versatile in various conditions.

Hot-Pressed: Limited to dry cutting but still adaptable for multiple materials.

Laser-welded diamond blades are designed for maximum durability. The high-strength bond between the diamond segments and the core allows these blades to withstand high speeds and heavy use. However, once the segments are worn down, the blade cannot be re-sharpened, and the entire blade may need replacement.

Hot-pressed blades offer a more maintainable option, as the segments can often be re-sharpened or replaced. This makes them more durable in the long run for lighter cutting tasks, especially when frequent blade adjustments are needed.

Durability Comparison:

Laser-Welded: Longer lifespan but non-repairable when segments wear down.

Hot-Pressed: Re-sharpening or segment replacement is possible, making them more adaptable over time.

Laser-welded blades are best for high-demand tasks in the construction industry. These include road construction, large-scale demolition, and cutting through thick slabs of concrete or granite. Their fast cutting speed and durability make them ideal for tough jobs.

Hot-pressed blades are ideal for precision cutting, such as when working with countertops, decorative stone, or fine masonry. These blades offer smoother, more accurate cuts and are commonly used in the stone and tile industries.

Application Recommendations:

Laser-Welded: Large-scale construction, demolition, and concrete cutting.

Hot-Pressed: Stonework, decorative pieces, and precision cutting tasks.

Choosing between laser-welded and hot-pressed diamond blades depends on your cutting needs. Laser-welded blades provide faster cutting speeds and better durability, ideal for heavy-duty tasks. Hot-pressed blades are more affordable and suitable for precise, fine-detail work. By understanding the differences in performance, cost, and applications, you can select the best blade for your project. Zhongzhi offers a range of high-quality blades that ensure value and exceptional performance, tailored to meet diverse cutting demands.

A: Laser-welded diamond saw blades are made by fusing segments to the core using a laser, offering higher durability and cutting speed. Hot-pressed blades use heat and pressure to bond segments, making them more affordable but less durable.

A: Laser-welded diamond saw blades are ideal for cutting concrete due to their faster cutting speed and durability, especially in heavy-duty applications.

A: Yes, hot-pressed diamond saw blades are typically more cost-effective because their manufacturing process is less complex compared to laser-welded blades.

A: Hot-pressed blades can be re-sharpened or have segments replaced, making them more maintainable and cost-effective in the long run.

A: Laser-welded blades provide better cutting efficiency, longer lifespan, and high-speed cutting, making them ideal for large-scale projects.