Views: 0 Author: Site Editor Publish Time: 2025-10-29 Origin: Site

Choosing the right diamond saw blade is essential for efficient and precise cutting. Whether you're working with concrete, granite, or tile, the right blade ensures cost-efficiency, performance, and longevity. In this article, we’ll explore the key differences between turbo and segmented diamond saw blades, helping you select the best option for your needs. You'll learn how each type performs in various applications and how to make the most out of your cutting tools.

A diamond saw blade is a cutting tool used for heavy-duty applications where standard saw blades cannot perform. These blades consist of industrial-grade diamond segments bonded to a metal core. The diamonds embedded within the segments are incredibly hard, allowing the blade to cut through tough materials like concrete, granite, stone, and ceramics.

The blade’s construction varies depending on the type of material it will be cutting and the required cut quality. Diamond saw blades are commonly used in construction, masonry, and demolition projects, making them indispensable tools for professionals in these fields.

These blades are available in various types, each designed for specific applications and cutting conditions. While diamond saw blades can be expensive, their durability and performance in tough environments often make them a worthwhile investment.

Selecting the wrong blade for a project can lead to inefficiency, poor results, and even premature wear on the tool. Several factors determine which blade is best for a job:

Material type: The hardness of the material you’re cutting impacts the blade selection. Harder materials like granite require a different blade than softer materials like brick.

Cutting method: Whether you are cutting dry or wet will influence the blade's performance. Some blades work better with water, while others perform better in dry conditions.

Required finish: If precision is essential, such as when cutting tiles or marble, the blade should provide smooth cuts.

Matching the right diamond saw blade to the task ensures that you get the best results, maximize the tool’s lifespan, and avoid unnecessary downtime.

Segmented diamond saw blades feature a rim with deep, visible grooves, often referred to as gullets. These gullets allow for better airflow, heat dissipation, and debris removal during cutting. The design helps maintain the blade's performance, especially when cutting hard and abrasive materials.

Segmented blades are typically used in dry cutting applications and excel in cutting tough materials like concrete, brick, and masonry. The deep gullets ensure that air can circulate freely around the blade, helping it stay cool during intense cutting tasks.

Fast cutting speed: Perfect for heavy-duty tasks that require quick material removal. If you are working on large-scale projects where speed is of the essence, segmented blades will significantly improve efficiency.

Long lifespan: These blades are durable and well-suited for extended use, especially in dry cutting conditions. Their aggressive cutting style and tough diamond segments make them resistant to wear and tear, which is ideal for construction sites.

Versatility: Segmented blades can be used in various applications, including demolition, masonry, and construction projects. They are suitable for both wet and dry cutting environments, though they perform best in dry conditions.

Tip: If you need to make fast cuts on tough materials like concrete or brick, segmented blades are an excellent choice for heavy-duty jobs.

Rough cut finish: Due to their aggressive design, segmented blades can leave rough, unfinished cuts, making them unsuitable for precision tasks. They are designed for efficiency and speed, but they compromise on the smoothness of the cut.

Faster wear on softer materials: Although excellent for hard materials, segmented blades tend to wear quicker when cutting softer materials like asphalt or brick. This can increase maintenance costs and reduce the overall lifespan of the blade.

Noisy operation: The aggressive cutting action can produce significant noise during use. If you are working in a noise-sensitive environment, the loud operation of segmented blades may not be ideal.

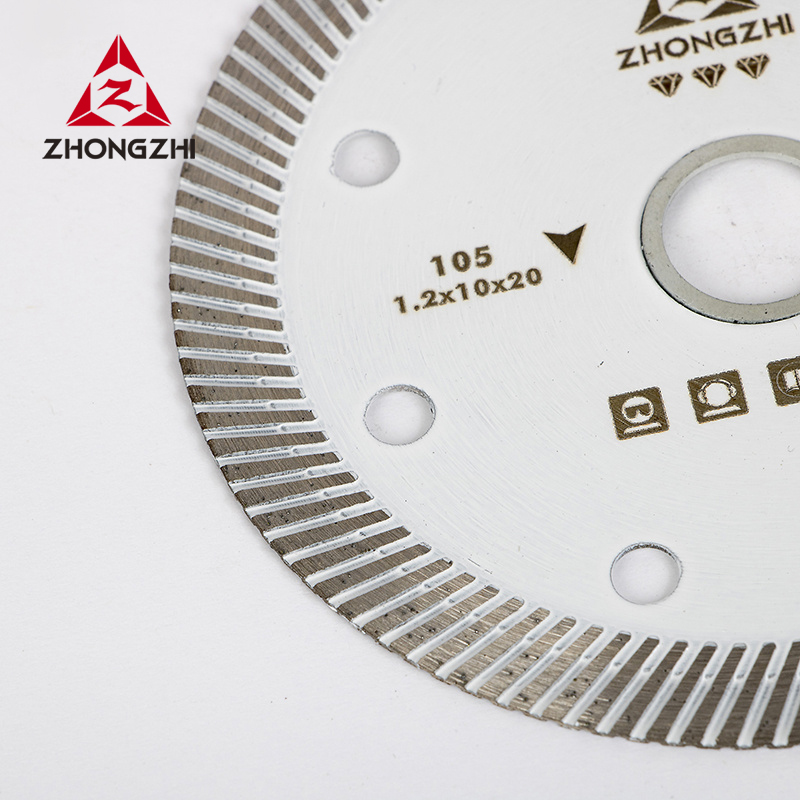

Turbo diamond saw blades are characterized by their serrated rim design, featuring small relief slots or grooves. These slots help manage heat and improve cooling during operation. Unlike segmented blades, turbo blades provide a smoother cutting experience and can be used for both wet and dry cutting.

Turbo blades are known for their versatility, providing a balance between speed and precision. They are widely used for cutting harder, denser materials such as tiles, granite, and stone.

Turbo blades are designed with smaller, continuous grooves in the cutting edge, which improves their cooling properties and makes them suitable for faster, smoother cuts. They are often preferred in settings where precision and speed are both important.

Balanced performance: Turbo blades offer a combination of speed and smoothness, making them ideal for projects requiring both precision and efficiency. Their balanced performance ensures that they can tackle a wide variety of materials without compromising on quality.

Versatile: They can be used for both wet and dry cutting applications, providing flexibility depending on the job. Whether you're working in a wet or dry environment, turbo blades are designed to perform effectively in both settings.

Lower noise and vibration: The design reduces vibrations, offering more control during cutting, which is ideal for precision tasks. The improved control makes them easier to handle, especially when working with intricate materials like tile or marble.

Tip: For cutting materials like granite or marble, turbo blades provide a smoother finish and less noise, making them ideal for delicate cutting tasks.

Not ideal for aggressive cuts: While they offer balanced performance, turbo blades are less effective in extremely hard materials that need aggressive cutting. If you need to cut through thick concrete or other dense materials, segmented blades may be more suitable.

Faster wear: The serrated design increases the surface area, causing turbo blades to wear out more quickly when used on tougher materials. However, they last longer than continuous rim blades in terms of cutting precision.

| Feature | Segmented Blades | Turbo Blades |

|---|---|---|

| Cutting Speed | Fast, ideal for aggressive cuts | Moderate, balance of speed and smoothness |

| Heat Dissipation | Effective heat dissipation due to gullets | Good heat dissipation with serrated rim design |

| Finish Quality | Rough cut, suitable for heavy-duty tasks | Smoother cut, suitable for precision tasks |

| Lifespan | Longer lifespan in heavy-duty applications | Moderate lifespan, faster wear on hard materials |

| Noise | Noisy due to aggressive cutting | Quieter with reduced vibration |

| Best For | Concrete, brick, block, and masonry | Tile, granite, marble, and stone |

Segmented blades are the best choice for aggressive cutting on materials like concrete, brick, and block. These blades are ideal for construction, demolition, and other heavy-duty tasks where speed is more critical than precision.

Dry cutting: Segmented blades perform well in environments where water is not available for cooling. Their deep gullets ensure that air can circulate around the blade, keeping it cool during operation.

Material hardness: These blades are designed to cut through harder, more abrasive materials with ease.

Tip: Choose segmented blades for high-speed, heavy-duty jobs like concrete cutting where a rougher finish is acceptable.

Turbo blades are perfect for cutting materials like tile, granite, and marble, where a smooth, clean cut is necessary. These blades also work well in both wet and dry cutting environments, making them versatile for a range of projects.

Moderate cutting needs: If your project requires a balance between speed and precision, turbo blades are the right choice.

Less aggressive tasks: Turbo blades are better suited for tasks where a cleaner finish is required rather than heavy-duty, high-speed cutting.

Choosing between turbo and segmented diamond saw blades depends on the materials and project requirements. Segmented blades excel at aggressive cutting, ideal for tough tasks like concrete cutting. Turbo blades offer a balanced performance, perfect for precision cuts on materials like tile and granite. Zhongzhi provides high-quality diamond saw blades that ensure durability and efficiency, offering a valuable solution for both heavy-duty and precision cutting projects.

A: Diamond saw blades differ in design and use. Segmented blades are aggressive and best for cutting hard materials like concrete, while turbo blades offer smoother cuts and are ideal for precision tasks such as tile and granite cutting.

A: For construction and demolition, segmented diamond saw blades are the better choice due to their fast cutting speed and durability when working with tough materials like concrete and brick.

A: Yes, turbo diamond saw blades can be used for both wet and dry cutting, making them versatile for various projects, especially when a smooth cut is required.

A: Segmented diamond saw blades are designed for fast, aggressive cutting of tough materials like concrete. Their deep gullets provide efficient heat dissipation, making them ideal for heavy-duty tasks.

A: Turbo diamond saw blades are generally more expensive than segmented blades, as they are designed for cleaner, smoother cuts and have a more complex design.

A: To extend the life of your diamond saw blade, ensure proper use, avoid excessive pressure, and choose the right blade for the material. Regular cleaning and proper storage also help maintain performance.